Motor Protection Relays

Thermal overload relays are supposed to be hot, that's how they work. Simply said, they are designed to emulate the temperature characteristics of the motor they protect.

3Φ motors protected by a motor protection relay

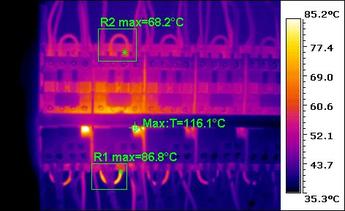

For a three phase motor, all three phases should have:

+ A similar temperature at the relay terminations.

+ Similar current measurements.

For a three phase motor, all three phases should have:

+ A similar temperature at the relay terminations.

+ Similar current measurements.

When Infrascan Thermal Imaging discovers a thermal anomaly, you should act as follows:

Where there is no current imbalance, or overload on the overload relay:

+ Tighten ALL terminations across the relay. Motor temperature varies due to loading, duty cycle, etc. Consequently; Relay terminations often work themselves loose. Check to see if the problem is resolved.

+ Check if similar motor protection relays feeding a similar load have a similar thermal pattern, and if not, contact the manufacturer to ensure the relay is within specifications.

+ Alternately - Where the unit is old or data is not available, replace the relay. Check to see if the matter is resolved. Check the motor terminations are within the standards either 60°C or 75°C.

+ Tighten ALL terminations across the relay. Motor temperature varies due to loading, duty cycle, etc. Consequently; Relay terminations often work themselves loose. Check to see if the problem is resolved.

+ Check if similar motor protection relays feeding a similar load have a similar thermal pattern, and if not, contact the manufacturer to ensure the relay is within specifications.

+ Alternately - Where the unit is old or data is not available, replace the relay. Check to see if the matter is resolved. Check the motor terminations are within the standards either 60°C or 75°C.

Where a considerable difference of temperature between phases is evident, you must investigate further:

+ Check the current at the motor terminations. (We sometimes see control circuitry erroneously placed on one of the (protected) phases. This creates false imbalances).

+ Check the motor bearings.

+ De-commission the motor or you may experience productions problems within a short period.

+ Check the resistance of the 3 phases.

+ If necessary, recondition or replace the motor accordingly.

+ Check the current at the motor terminations. (We sometimes see control circuitry erroneously placed on one of the (protected) phases. This creates false imbalances).

+ Check the motor bearings.

+ De-commission the motor or you may experience productions problems within a short period.

+ Check the resistance of the 3 phases.

+ If necessary, recondition or replace the motor accordingly.

Single Φ motors protected by a motor protection relay

For single phase motors protected by a 3 phase relay: All three terminations should have similar temperatures at the contactor/relay terminations. This is most often NOT the case, despite the same current running through the 3 poles of the relay. When testing, assume this imbalance is due to a number of reasons:

+ The bearings on the motor are worn causing drag. Inspect the motor for any anomolies and repair accordingly.

+ The relay is set very low and operates inefficiently at low currents.

+ The relay is faulty.

For single phase motors protected by a 3 phase relay: All three terminations should have similar temperatures at the contactor/relay terminations. This is most often NOT the case, despite the same current running through the 3 poles of the relay. When testing, assume this imbalance is due to a number of reasons:

+ The bearings on the motor are worn causing drag. Inspect the motor for any anomolies and repair accordingly.

+ The relay is set very low and operates inefficiently at low currents.

+ The relay is faulty.

Click on the above for larger images

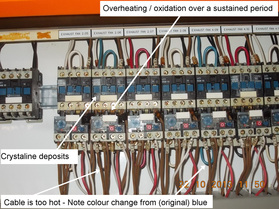

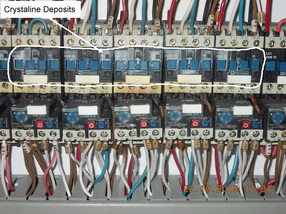

Crystalline Deposits

These deposits appear in warmer relays left unattended over a long term. We have not been able to establish what causes these crystals to appear:

These deposits appear in warmer relays left unattended over a long term. We have not been able to establish what causes these crystals to appear:

Click on the above for larger images

What happens inside the relay:

Overload relays recognise balanced overload events as well as unbalanced currents. These relays heat up (and ultimately trip) on:

+ Termination faults

+ Stator winding faults

+ Earth faults

+ Single phasing events

+ Overload such as bearing failure

+ Locked rotor events

Overload relays recognise balanced overload events as well as unbalanced currents. These relays heat up (and ultimately trip) on:

+ Termination faults

+ Stator winding faults

+ Earth faults

+ Single phasing events

+ Overload such as bearing failure

+ Locked rotor events

Note

Ensure your plant equipment operates within the recommended and statutory standards at all times. All safety guidelines should be observed.

Ensure your plant equipment operates within the recommended and statutory standards at all times. All safety guidelines should be observed.